My name is Augusto Iwao Eto, and I’m a Lean consultant specializing in Kaizen, Karakuri, and process development. I was born in São Paulo, Brazil, and I have always been passionate about exploring new techniques, methods, and processes to address challenges and enhance the work environment.

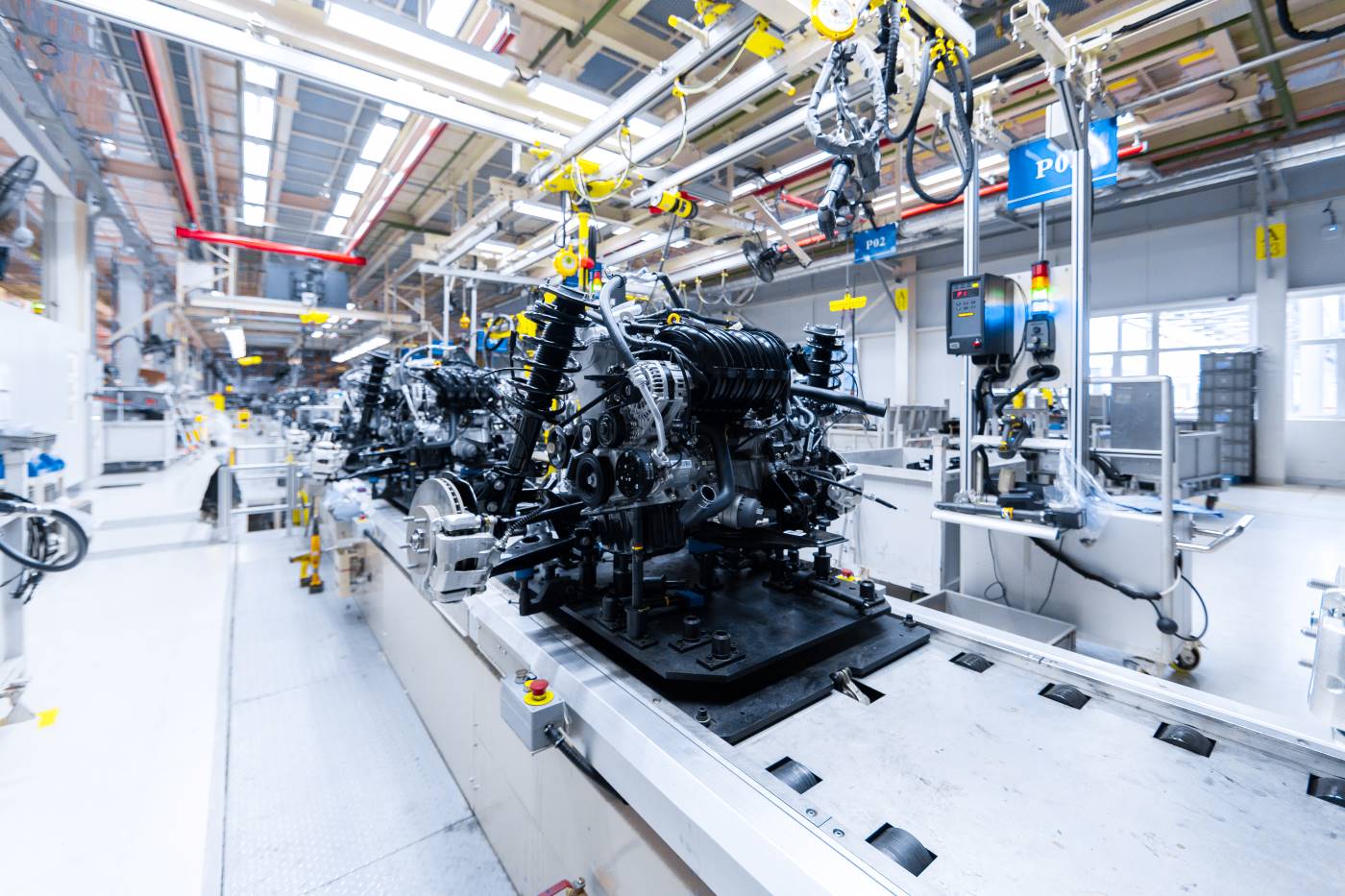

My background includes experience as a Process Analyst and Industrial Designer, with expertise in mechanical and electronic design, quality management, production, and safety. I spent a decade working at Toyota do Brasil in São Bernardo do Campo, initially in the Product Engineering sector and later in technical consultancy within the welding industry.

Subsequently, I embraced the challenge of working abroad and spent 24 years in Japan, primarily in the automotive sector. During this time, I immersed myself in a new culture characterized by discipline, innovative thinking, advanced techniques, and production processes deeply rooted in the Toyota Production System (TPS).

Today, I continue to embrace learning as an ongoing journey, collaborating with various companies to assist Genba sectors and individuals in enhancing safety, reducing waste, and optimizing process flow through Kaizen. My role involves both teaching and overseeing the learning process, tracking progress, and assessing the results achieved through collaborative efforts.