Who hasn’t recently been attracted to or curious about what IoT, Big Data, AI, Additive Technology, VR, BI or another “Wave 4.0” term is, trying to imagine how to use these technologies in their business segment or simply afraid of being left out and labeled a Jurassic? It’s the same kind of phenomenon that occurred and still occurs with the TPS (Toyota Production System) and Lean Manufacturing, where a pole of curiosity and attraction has been created with the jargon of methodologies full of acronyms and Japanese words, such as Kanban, Heijunka, 4S+S, Mieruka, FMDS… and not infrequently Lean knowledge is confused with knowledge of this soup of letters. In this article we’ll see that both the Industry 4.0 Digital Revolution and Lean Manufacturing go further and forge results synergistically when strategically structured.

Who hasn’t recently been attracted to or curious about what IoT, Big Data, AI, Additive Technology, VR, BI or another “Wave 4.0” term is, trying to imagine how to use these technologies in their business segment or simply afraid of being left out and labeled a Jurassic? It’s the same kind of phenomenon that occurred and still occurs with the TPS (Toyota Production System) and Lean Manufacturing, where a pole of curiosity and attraction has been created with the jargon of methodologies full of acronyms and Japanese words, such as Kanban, Heijunka, 4S+S, Mieruka, FMDS… and not infrequently Lean knowledge is confused with knowledge of this soup of letters. In this article we’ll see that both the Industry 4.0 Digital Revolution and Lean Manufacturing go further and forge results synergistically when strategically structured.

WHAT IS YOUR PURPOSE?

Some time ago, some friends in a WhatsApp group were talking about the best options for buying cars. As I worked for Toyota, they started asking me about the brand’s vehicles. As in almost every conversation (on any subject), there’s always someone who wants to prove that they’re an expert and starts questioning some details, parading their technical “knowledge”. At one point, someone asked why a certain compact model of the brand didn’t have VSC, ATC, because some of the competition did. Another friend didn’t mince his words and said that, on the other hand, it came with Dual-VVTi and HDMID. At this point, I asked everyone what purpose they had for their vehicle, because the equipment would make sense according to what they expected from their car. In the same way, when we look at our Business, we have to look for our purpose (what we are here for) and vision (where and when we want to be in a future state). If we know our starting point (our current state), we’ll have an idea of what we need to get there and only then will we start looking for how to get there. This is where Lean methodologies and Industry 4.0 technologies come in. If this logic is reversed, with the focus on techniques, this journey will be lost along the way (in fact, we won’t even know which path to take…). At this point, it is undeniable that technological evolution is bringing new possibilities and establishing new business paradigms and ways of interacting with customers, and it is essential to critique the business model itself in this severely changing environment so that the organization does not simply perish in the middle of this journey. It’s a bit like what Toyota did when it declared the end of the Age of the Automobile and decreed the Beginning of the Mobility Industry in its business focus, clearly defining its Purpose and Future Vision. What about you? Have you thought about your Purpose?

I HAVE MY PURPOSE. AND NOW?

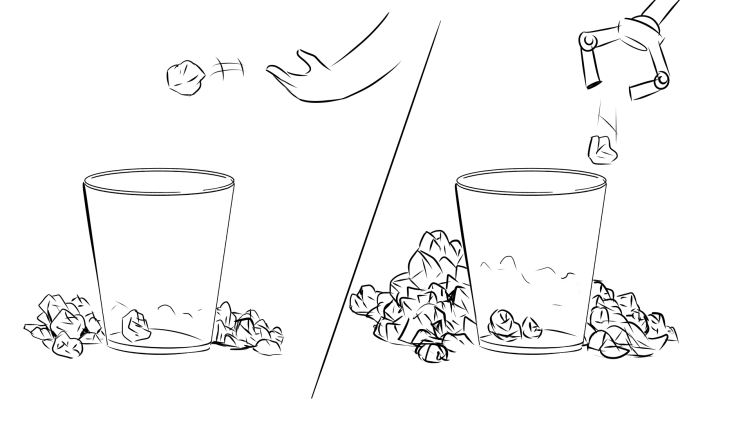

Without a shadow of a doubt, converging digital technologies such as iOT, Clouding, Big Data, AI, 5G and Mobile Devices, provide a wide range of new business possibilities, help us to see and analyze our data better and bring more speed to our internal processes, as well as enabling tasks that were previously very costly or difficult to perform, with the use of VR, AR and Additive Technology for example. Once you have your purpose, one precaution to take is to critique your internal processes before automating and connecting them digitally. This is where the old lessons learned from Lean and TPS come in when it comes to identifying and eliminating waste. The combination of Lean Kaizen and digital transformation brings a great synergy of results, but on the other hand the digitalization of poorly designed, poorly connected processes, which originally generate waste, has the capacity to cause an acceleration of this waste with the indiscriminate use of digital technologies. The digital revolution is here to stay. It is already changing the way society relates to each other, and is transforming business models and consumer relations. There will be no turning back from this phenomenon, and the need for physical processes to keep up with the speed of this change makes the competitive advantages of combining it with a Lean transformation journey all the more relevant. The concept is easy to understand. So where do I start?

ARE WE READY? WHERE DO I START?

The entire transformation process, whether Lean, Digital or both, basically has the following fundamental aspects:

1. Mindset and Governance of Continuous Improvement and Innovation

Every transformation presupposes a continuous process of change, which has to be incorporated not as a momentary rupture, but as an element within the day-to-day running of the business, which has to be assimilated and managed on an ongoing basis. Last year, a colleague asked me when this wave of change would end. I don’t know if my answer was encouraging, but I told him that from my point of view, we would have to forget about static working environments and incorporate the dynamics of change into our daily lives, like a surfer who never expects calm seas or surfs against the wave, but rather gets the best out of the biggest waves… and always improves and seeks out the biggest challenges.

2. Cultural Refinement and Activation of Competencies that Support Transformation

Both digital and lean transformation presuppose the assimilation of new values and the belief in the new as a positive and beneficial aspect. This means a process of refinement through the creation of a collective sense of the need for transformation, leadership with genuine faith in the strategies, the development of skills in the methodologies and technologies that support transformation, experimentation and a key aspect that is the formation of a new profile of competencies (soft skills) that support this process. Aspects such as resilience, adaptability and agility will become increasingly important. All of the above must not only be dealt with in general terms, but the actions for this Cultural Refinement must be planned and managed.

3. Creation or Review of Business Support Structures (Organization and Processes)

This point touches very strongly on Lean Transformation. The review of organization and processes, in addition to the search for agility, accuracy and lean models without waste, is a precondition for Digital Transformation, otherwise you run the risk of digitizing waste itself. On the other hand, by combining Lean and Digital practices, the results become synergistic, boosting the process of eliminating waste. In this way, the use of some methodologies begins to make sense, such as IMF/VSM and TBP/LBP for improving process flow and eliminating Muri, Mudá and Murá, and using IoT, Big Data, AI Analysis and Decision, BI Summarization and other digital technologies as part of the solution to achieve its purpose.

4. Critique and Review your Business Model

A famous phrase, and one that is particularly popular these days, attributed to Charles Darwin, says that “not the strongest or the most intelligent survive, but the most adaptable”. In fact, this phrase was uttered in 1963 by Leon Megginson, a professor at Louisiana State University (USA) about the Theory of the Evolution of Species and wrongly attributed to Darwin. The sudden change in the business environment brought about by the Digital Revolution could have a cataclysmic effect on your current business model, as the Ice Age did for the Dinosaurs. A strong turnaround may be necessary if you don’t want to miss out on the Noah’s Ark of history. Many companies, such as Blockbuster, the global giant in the DVD movie rental business, have simply ceased to exist because of technological evolution. In this case, the cataclysm for them was Digital Streaming technology, which culminated in their bankruptcy and extinction in 2011. Other more cautious companies, such as Toyota, are already jumping to adapt to the new times. In Toyota’s case, it has gone from being a car manufacturer to a provider of mobility solutions, establishing a strong change in its business concepts. What about you? Are you comfortable with your business model?

5. Focus on changing customers

Yes, customers are also drastically changing their habits and expectations as a result of the digital transformation. This is reflected not only in the consumer market, but also in B2B relationships. Customers increasingly expect faster responses, greater accuracy, flexibility and the ability to meet more customized demands, as well as more personalized attention and support. This will require efforts not only from digital technologies, but also from a very smart, synchronized and waste-free internal process, and of course, all of this based on a strategy based on a clear reading of the transformation of what your customer expects, or will expect from now on, in response to their demands.

6. Monitor competitors’ movements

In a dynamic of transformation, those who are smarter react faster in the Dance of the Chairs, so it’s important to keep an eye on the movement of the competition so as not to be left behind. The landscape of players has changed a lot with the very transformation in business focus, creating a very large asymmetry. For decades, for example, the struggle in the global automotive market has had very well-defined players, such as GM, Toyota, Ford and VW, to name but a few. With the shift in focus to the Mobility Market, some new entrants such as Amazon, Google and Tesla itself, which was already on the list, but lower down in the automotive competition, will unbalance this equation with competencies that are very different from the traditional automotive market, such as AI technologies in autonomous cars and digital technologies for sharing and rental services.

7. Skill in the use of data

This is a crucial point where Lean and Digital intersect once again. Systematically analyzing data, consolidating it using visual methods (Mieruka) and linking this to control actions, systematic problem solving and continuous improvement (Kaizen) are one of the main streams of Lean practice. Automated collection resources, the use of Big Data, BI (Business Intelligence) and AI (Artificial Intelligence) technologies enhance the response of analysis and decision making, shortening time and bringing more assertiveness, but many stop the process at collecting and monitoring data, simply accumulating it and not connecting its use to ‘nobler’ causes within the organization.

8. Mastering technology

Many people ask me if you need to become a digital expert to face this New Age. Just as you don’t need to be a Lean Specialist to promote a Lean transformation, you don’t need to become a digital expert to face a digital transformation in your company. What is necessary is to know what each Methodology and Technology is capable of in terms of response within your Business context. It’s more or less like a doctor prescribing a medicine: you don’t need to know exactly how it’s formulated or produced, but you do need to know what it’s for and how the active ingredient acts in the body, knowing how to prescribe it according to the situation and having control over how the patient’s condition evolves. In other words, technological mastery primarily involves knowing why to use it, when to use it, how much to use and how to use it, how it works and what effects the technology or methodology has. Once again we come up against our purpose: without a purpose, even the most advanced technology in the world will make no sense at all. Try analyzing these 8 points above to see how prepared your organization is to transform itself, and perhaps it will become clearer where you have competitive advantages and especially where you will have to work harder and faster to secure your place in the sun in a future that may be closer than we think.

BUILD THE MAP TO YOUR PLACE IN THE SUN

This assessment of strengths and weaknesses, as well as a short-, medium- and long-term plan, must be consolidated and visualized so that everyone can see the future state we imagine and want for our business, and the path to be taken from the starting point, which in each of the 8 aspects we looked at earlier may be a little further ahead or a lot further back, putting everything into a visual roadmap so that absolutely everyone can see it, understand its context, move in the same direction and at the right speed. Anyone who is familiar with Lean or TPS will have smelled Hoshin Kanri (Methodology for Deploying Guidelines, Objectives and Goals) in the air. Again, the example that Digital Transformation has synergy if assisted and guided by methodologies that come from Lean Culture. This collective perception created by the Hoshin is very important at times of Transformation, because for everyone it will be a Path never trodden, and the unknown and the uncertain usually bring insecurity, anxiety and discomfort, and the Hoshin will be the GPS that will bring more confidence and tranquillity about the path to follow to reach your little place in the Sun, and the Technologies and Methods will finally stop being an indecipherable Soup of Letters. Oh, and remember that from now on your place in the sun will be constantly changing, so this is a process that will never end.

Get used to it…

Edson Nagamachi,

Senior Director of Honsha.ORG, metallurgical engineer from the Polytechnic School of the University of São Paulo and Post-Graduate in Business Administration Specialization from the Getúlio Vargas Foundation (FGV-SP / GVNext), with more than 30 years of experience in Toyota Mercosur and in all Toyota do Brasil production plants, in Project Management, Industrial Operations and Production Engineering. He has worked as Director of Innovation and Industry 4.0 at Toyota do Brasil, as Director at the São Bernardo do Campo and Porto Feliz plants, Project Management Manager at Toyotas in Brazil, Argentina and Venezuela, always with a focus on flow design and innovative processes.

Click here to read other articles from Honsha.ORG.

Follow us on YouTube.

Your Content Goes Here

Your Content Goes Here

Your Content Goes Here