The industrial equipment sector requires a high level of efficiency, quality, and flexibility to meet customer demands and remain competitive in the market. In this context, implementing Lean and the Toyota Production System (TPS) can bring numerous unique benefits to companies in this sector.

Let’s explore specific examples of how Lean and TPS can help industrial equipment companies reduce waste, improve production efficiency, enhance equipment quality, increase production flexibility, and strengthen supplier relationships.

Reduction of Material Waste: Through Lean and TPS practices, industrial equipment companies can significantly reduce material waste, which is especially valuable in this sector given that many materials used in equipment manufacturing are costly and/or difficult to procure. For example, implementing Kanban systems can help control parts and material inventory, avoiding over-purchasing and reducing material loss due to obsolescence.

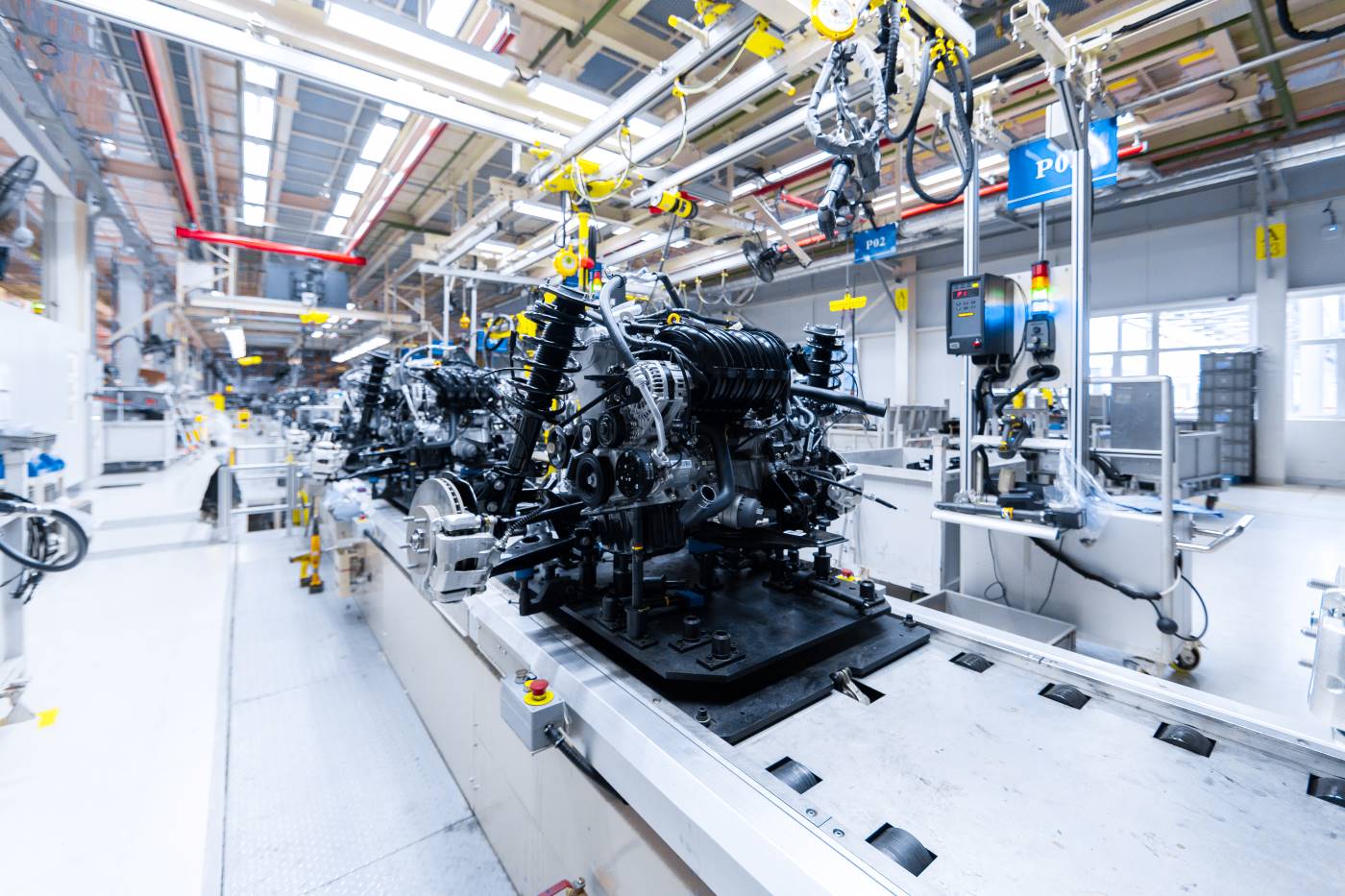

Improvement in Production Efficiency: Applying Lean and TPS can also help industrial equipment companies improve production efficiency. This is particularly important in this sector, where many products are custom-made and require a high level of customization. With these methodologies, companies can reduce production time, increase production capacity, and optimize resource utilization.

Enhanced Equipment Quality: TPS is renowned for its focus on product quality. By implementing this methodology, industrial equipment companies can improve product quality, reduce defect rates, and increase customer satisfaction. This is critical in this sector, where equipment quality directly impacts the safety and efficiency of production processes.

Increased Production Flexibility: Industrial equipment companies must be able to adapt quickly to changing customer demands and market conditions. Implementing Lean and TPS enables these companies to become more flexible and agile in custom equipment production, reducing response time and boosting customer satisfaction.

Improved Supplier Relationships: The industrial equipment sector relies on an extensive network of suppliers to obtain the materials and components necessary for manufacturing. By applying TPS, companies can enhance communication and collaboration with suppliers, potentially reducing production costs and improving the quality of materials and parts used in equipment manufacturing.

If you operate in the industrial equipment sector and are seeking ways to improve the efficiency and quality of your production processes, read on to discover how Lean and TPS can help your company achieve these goals.