The implementation of Lean methodology and the Toyota Production System (TPS) in the automotive sector offers a range of benefits, including cost reduction, improved safety, encouragement of innovation and product development, and supply chain strengthening. These advantages contribute to enhancing efficiency, quality, and competitiveness in the automotive industry, enabling an agile response to market demands and a strategic advantage in an increasingly challenging business environment.

The automotive sector is one of the industries that benefit most from the application of Lean and TPS. These methodologies were initially developed by Toyota to improve efficiency and quality in car production.

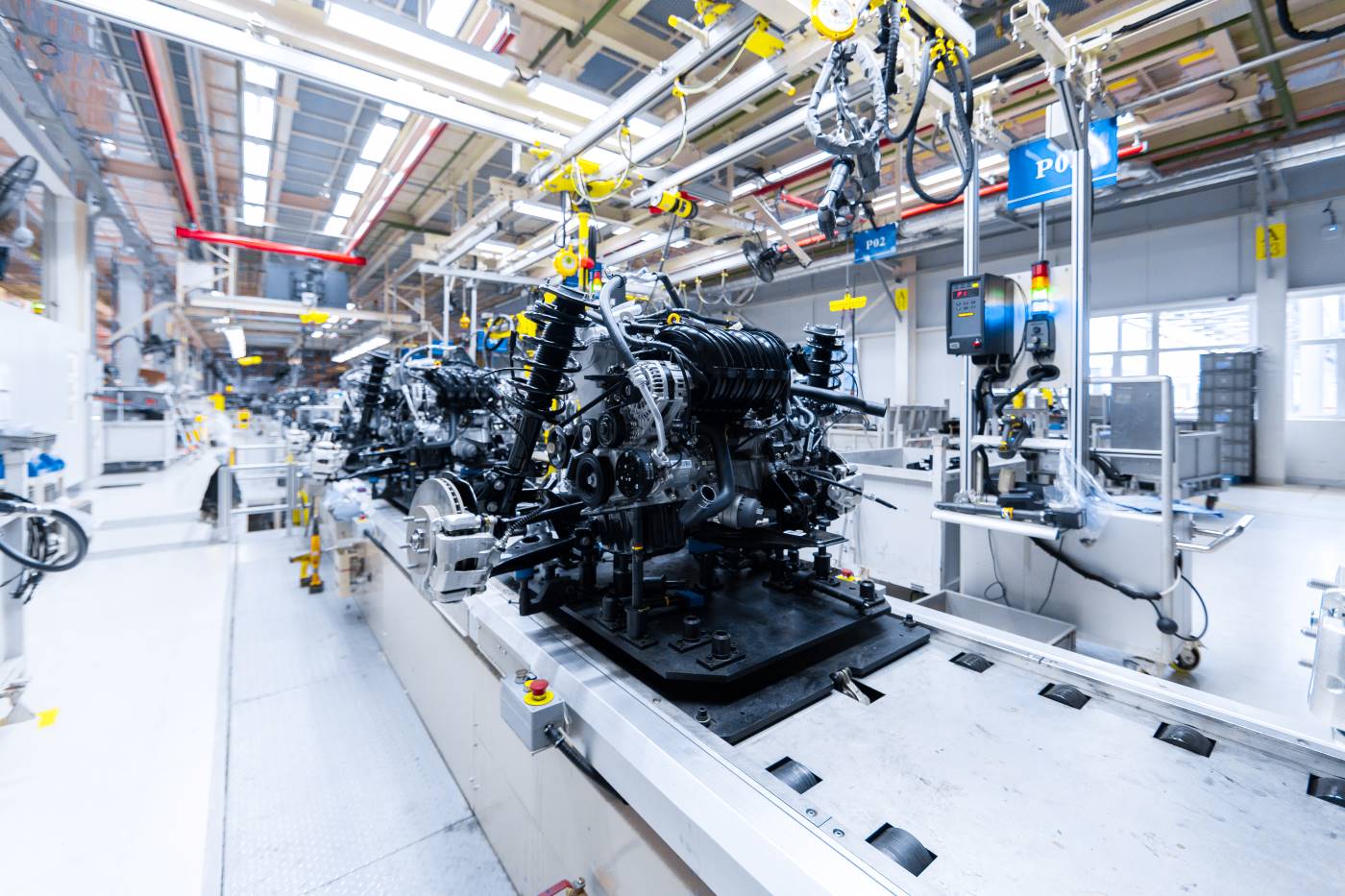

Production efficiency: The automotive industry faces high demands for efficiency in vehicle production, and Lean and TPS are particularly suited to meet this need. By eliminating waste and optimizing workflows, automotive companies can achieve more efficient production, reducing the time and resources needed to manufacture a vehicle. This results in increased productivity and the ability to meet customer demands more quickly and efficiently.

Superior quality: Quality is a fundamental priority in the automotive sector, and Lean and TPS methodologies emphasize the importance of quality across all processes. Implementing practices like “jidoka,” which involves detecting and immediately addressing quality issues, allows automotive companies to achieve superior quality levels, reducing defects and ensuring customer satisfaction. This is crucial for brand reputation and customer loyalty.

Cost reduction: The automotive sector is highly competitive, and cost reduction is a constant priority. Applying Lean and TPS enables automotive companies to identify and eliminate waste in their processes, leading to significant cost savings. This includes reducing inventory, optimizing resource use, and eliminating non-value-added activities. With lower costs, companies can improve profit margins and become more competitive in the market.

Production flexibility: The automotive industry is subject to rapid changes in consumer preferences, market demands, and technological advancements. Lean and TPS methodologies allow automotive companies to become more flexible in production, quickly and efficiently adapting to these changes. For example, adopting practices like Single-Minute Exchange of Die (SMED) can significantly reduce tool changeover time and enable agile production of different vehicle models, better meeting market demands.

Continuous innovation: The automotive industry is driven by innovation, both in technology and design. Lean and TPS foster a culture of continuous improvement and innovation at all organizational levels. By involving employees in identifying and solving problems, automotive companies can reap significant benefits in product and process innovation. This supports the development of more advanced, sustainable, and appealing vehicles for consumers.

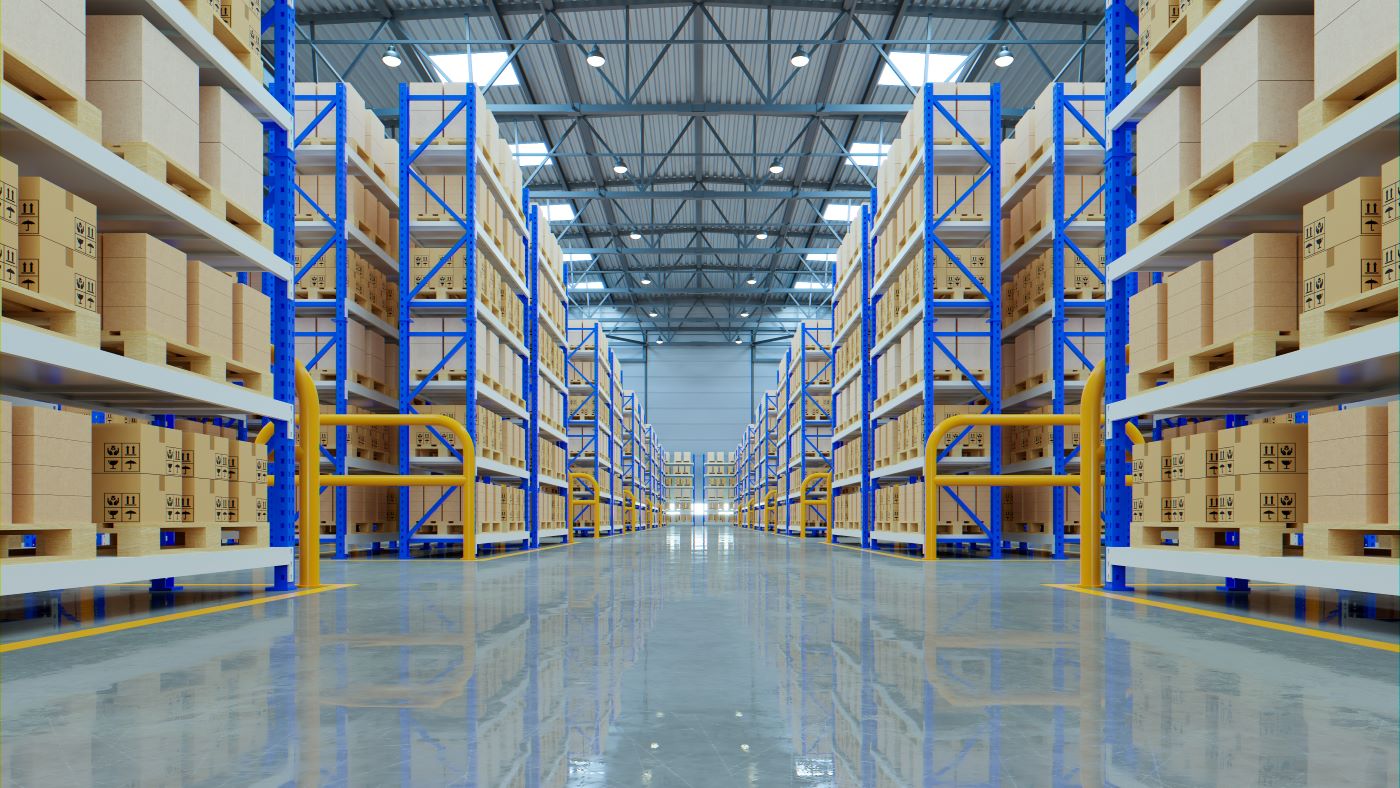

Strengthening a solid supply chain: Implementing Lean and TPS in the automotive sector extends beyond manufacturing to the entire supply chain. Automotive companies can closely collaborate with suppliers to apply Lean principles, such as “just-in-time” production and inventory reduction. This enhances synchronization between vehicle production and component supply, reducing delays and minimizing costs associated with excessive inventory storage.

Strengthening safety culture: Safety is a critical concern in the automotive industry, both for employees and customers. Lean and TPS methodologies emphasize the importance of workplace safety, encouraging the adoption of practices and processes aimed at accident and injury prevention. By fostering a strong safety culture, automotive companies can reduce the number of incidents and provide a safer and healthier work environment.

Focus on sustainability: The automotive industry is increasingly aware of the importance of environmental sustainability. Lean and TPS methodologies encourage waste reduction and efficient use of natural resources, contributing to sector sustainability. Automotive companies can adopt practices such as proper waste management, use of recyclable materials, and integration of cleaner technologies in their production processes. This not only reduces environmental impact but also meets the expectations of environmentally conscious consumers.

Improved customer satisfaction: The primary goal of implementing Lean and TPS in the automotive sector is to meet and exceed customer expectations. By eliminating waste, improving quality, reducing lead times, and offering innovative products, automotive companies can provide a more satisfying vehicle purchase and ownership experience for their customers. This strengthens brand reputation, increases customer loyalty, and drives business growth.

Increased global competitiveness: The automotive sector is highly competitive on a global scale. Lean and TPS implementation allows automotive companies to become more competitive by improving efficiency, quality, flexibility, and innovation. With a Lean approach embedded in their organizational culture, automotive companies can stand out in the global market, achieve a leading position, and secure a lasting competitive advantage.