The implementation of Lean and the Toyota Production System (TPS) can bring unique benefits to the chemical sector by optimizing production processes and reducing operational costs. The chemical segment encompasses the production of various types of chemical products, ranging from raw materials to finished goods. This industry is considered strategic for the economies of many countries, as its products are essential for various sectors, including pharmaceuticals, food, and automotive.

However, the production of chemical products involves complex processes that require special attention, such as inventory management, waste reduction, and ensuring product quality.

Let’s explore in an instructional manner, with examples, the unique benefits that the chemical sector can gain from implementing these methodologies.

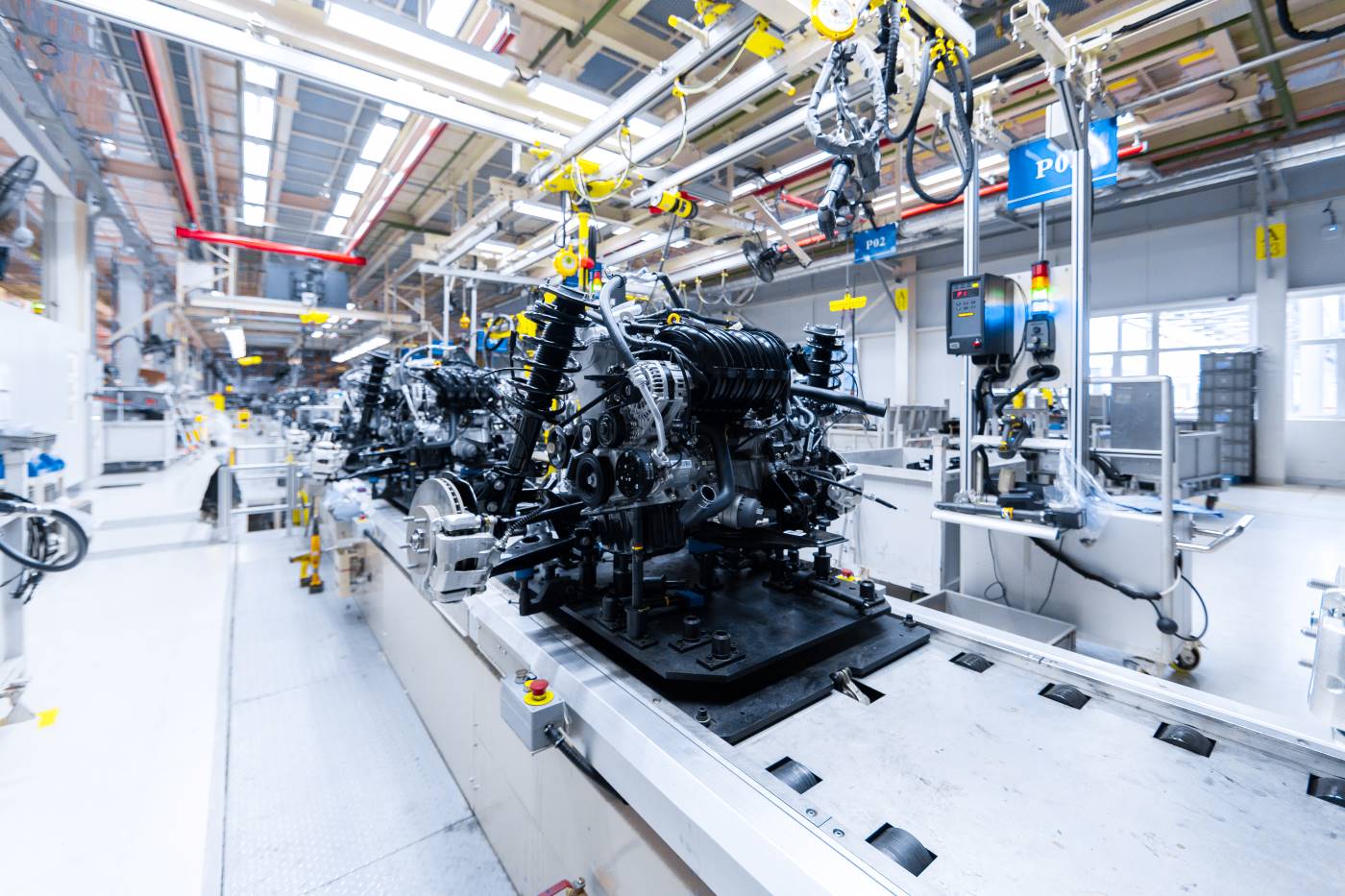

Reduction of Changeover Time: The chemical sector deals with the production of various types of chemical products, often necessitating the change of equipment and tools to accommodate the production of a new product. The application of TPS can help reduce changeover time through the implementation of standardized workflows and the use of data analysis tools to identify bottlenecks and areas for improvement. For instance, a chemical company may utilize Single-Minute Exchange of Die (SMED) techniques to minimize product changeover time, thus enhancing production efficiency.

Waste Reduction: The chemical sector manages expensive and hazardous materials, including raw materials and chemicals. Lean methodologies can assist in minimizing waste by ensuring materials are stored and utilized appropriately. For example, a chemical company may employ Lean principles to identify and eliminate unnecessary processes, thereby reducing production time and preventing excessive chemical output.

Improvement in Product Quality: The quality of chemical products is crucial for customer satisfaction and brand reputation. The application of TPS can enhance the quality of chemical products by reducing wait times and increasing process efficiency. For instance, a chemical manufacturer may leverage TPS to ensure that chemical products are produced with precision and quality, thereby increasing customer satisfaction.

Enhanced Inventory Management: Inventory management is vital in the chemical sector, as many chemicals have expiration dates and require proper storage. The application of Lean and TPS can improve inventory management by reducing excess stock and ensuring that chemical products are always available for production. For example, a chemical manufacturer might use Kanban systems to monitor raw material inventory and ensure that chemical products are produced swiftly and efficiently.

Cost Reduction: The implementation of Lean and TPS can help a chemical company reduce costs by eliminating waste and optimizing processes. For instance, a chemical manufacturer may utilize Lean methodologies to decrease production time for chemical products, thereby increasing employee productivity and lowering operational costs.

It is important to note that each chemical industry has its specificities and can benefit uniquely from the application of these methodologies. Therefore, it is essential that the implementation is carried out by specialized professionals with knowledge of the sector.