The food industry is one of the most crucial sectors in the global economy, responsible for producing and distributing food to millions worldwide. However, this industry also faces a range of challenges, including the need to reduce waste, improve product quality, enhance process efficiency, and lower costs. To address these challenges, many companies in the sector are implementing Lean and TPS methodologies, which help to improve process efficiency and quality, minimize waste, and increase customer satisfaction.

We will explore the unique benefits that the food industry can gain by adopting these methodologies, presenting practical examples of how they can be applied to improve process and product quality and efficiency.

Reducing Food Waste: Food waste is a serious issue in the food industry, impacting both profitability and the environment. Applying Lean and TPS can help reduce food waste through techniques like using Kanban to control raw materials and finished product inventories, implementing standardized workflows to decrease wait times, and employing data analysis tools to identify areas of waste.

Enhancing Product Quality: Product quality is critical in the food industry as it directly affects customer satisfaction and regulatory compliance. The application of TPS can help food companies improve product quality, reduce errors, and enhance customer satisfaction. For instance, implementing quality monitoring systems can help identify improvement areas and ensure compliance with safety and quality standards.

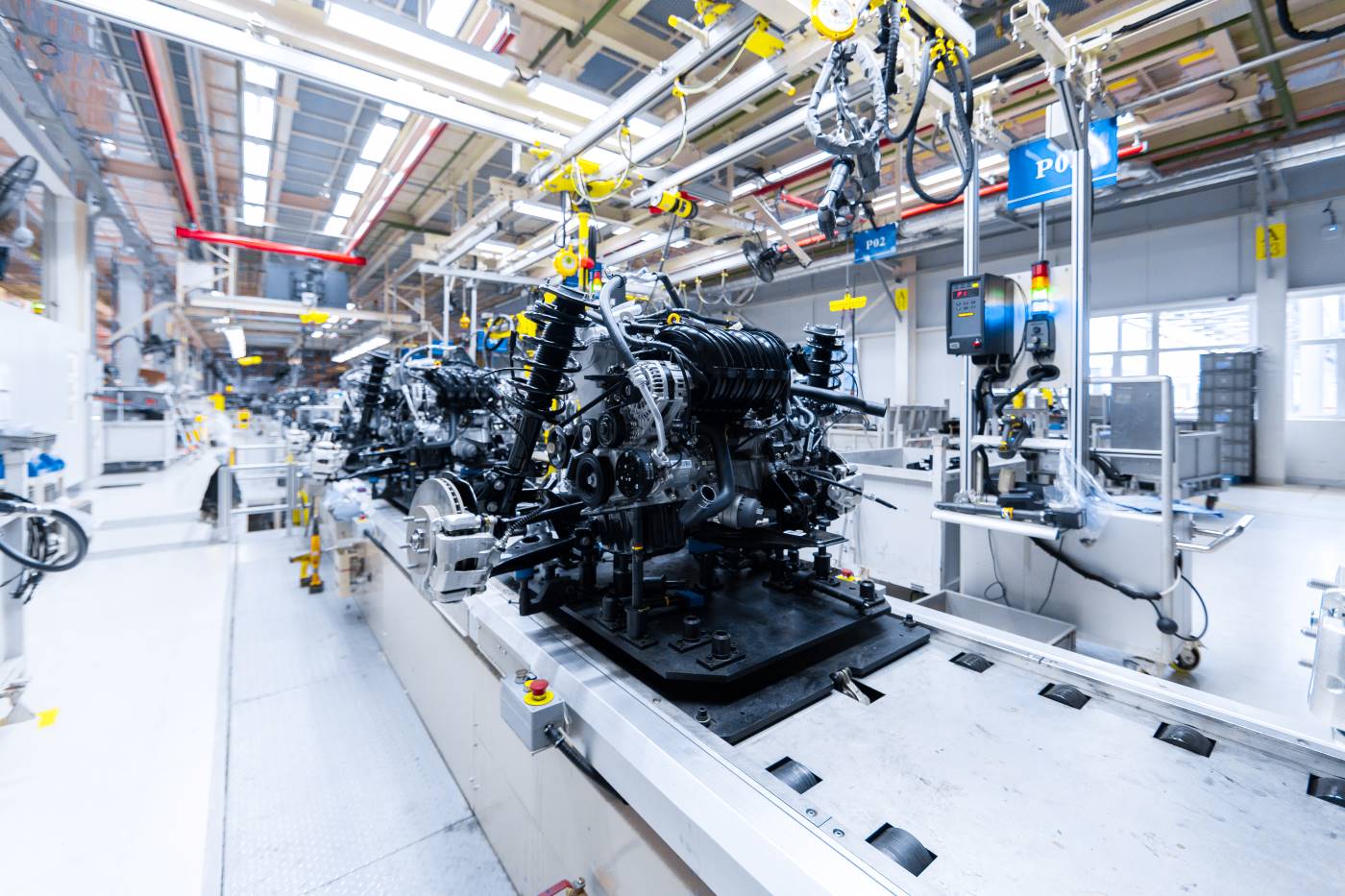

Increasing Process Efficiency: The food industry is highly competitive, requiring companies to be agile and efficient to meet customer demands. Applying Lean can help food companies improve their process efficiency by reducing customer wait times and increasing service capacity. For example, standardized workflows can reduce production time and boost factory productivity.

Cost Reduction: Applying Lean and TPS can help food companies reduce costs by eliminating waste and optimizing processes. For example, implementing visual management systems can quickly identify high-demand areas and allow for more efficient resource allocation, reducing production costs.

Greater Flexibility in Service: The food industry is subject to demand fluctuations, which can vary by season, events, and promotions. By adopting Lean and TPS, food companies can become more flexible and agile in meeting diverse customer needs, reducing response times and enhancing customer satisfaction.