Hello, I’m João Alberto Teouro, and I hold qualifications in Machining, Welding, Assembly, Painting, and Quality Process Technology. I received training in TPS (Toyota Production System) at TMC (Toyota Motor Corporation) in Japan under the Japanese government program (AOTS) in the year 2009.

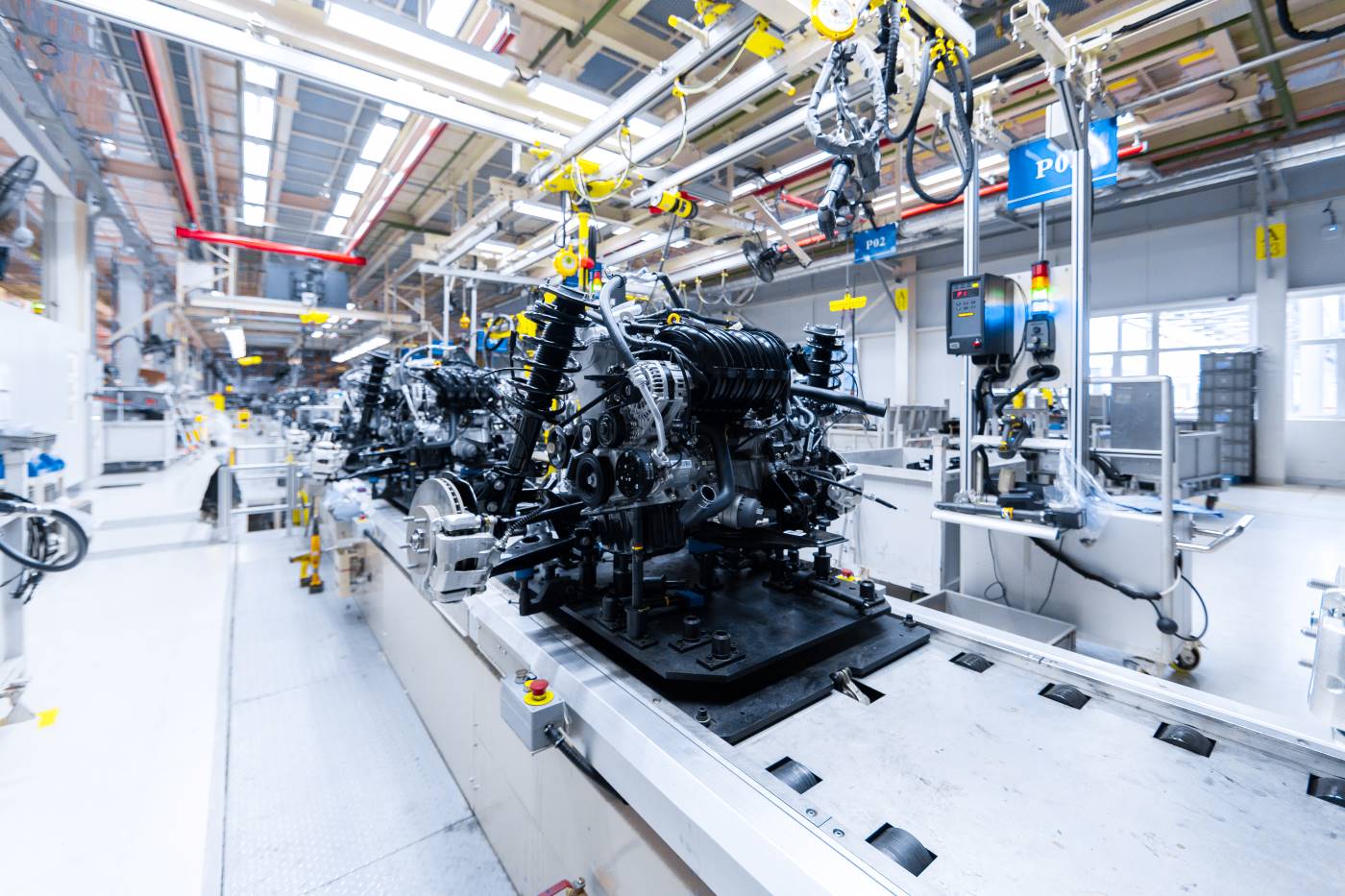

With over 23 years of experience working at Toyota do Brasil, I have served as a Production Process Manager, where I have been involved in the implementation of new projects. My responsibilities included machine preparation (programming and tooling development), conducting CP and CPK Capability Studies, overseeing layout design, and managing infrastructure aspects (electrical, hydraulics, etc.). I also played a role in the preparation of standard operations documents, such as Sanpyo (The 3 Documents) and Operational Standards.

Furthermore, I have managed KPIs and sub-KPI indicators, proposing actions to both maintain and enhance their performance.

I have conducted various training programs, including but not limited to:

⦁ TJI – Work Instruction Training

⦁ TPM – Total Preventive Maintenance

⦁ Role of the Leader Program (Production Coordinator)

⦁ TP – Standardized Work

⦁ ISO 14000

⦁ TBP – Toyota Business Practices

⦁ PDCA – Plan, Do, Check, Act

⦁ Quality Assessment – Quality Assessment by TMC

⦁ 5S – Organization and Standardization Management

⦁ On the Job Training – Training and development at work

⦁ Workplace safety

⦁ KAIZEN

⦁ CCQ – Quality Control Circle

⦁ 7 Quality Tools

At present, my specialization lies in project management, encompassing everything from layout planning to process delivery, all guided by defined work standards. My professional experience extends to working with more than ten companies, where I’ve played a pivotal role in implementing Lean Culture. Some of the companies I’ve worked with include Fleximedical, Volvo, Siemens, HellermannTyton, Zaraplast, Raízen, Engemet, GCABE, among others.