In the pharmaceutical sector, implementing Lean and the Toyota Production System (TPS) can provide unique benefits, such as reducing medication production time, minimizing waste, improving medication quality, enhancing inventory management, and lowering costs.

Lean and the Toyota Production System (TPS) are widely used methodologies across various industries, aimed at improving process efficiency, reducing costs, and increasing customer satisfaction.

Let us delve into how the pharmaceutical sector can benefit from applying Lean and TPS, driving significant improvements in its processes and services.

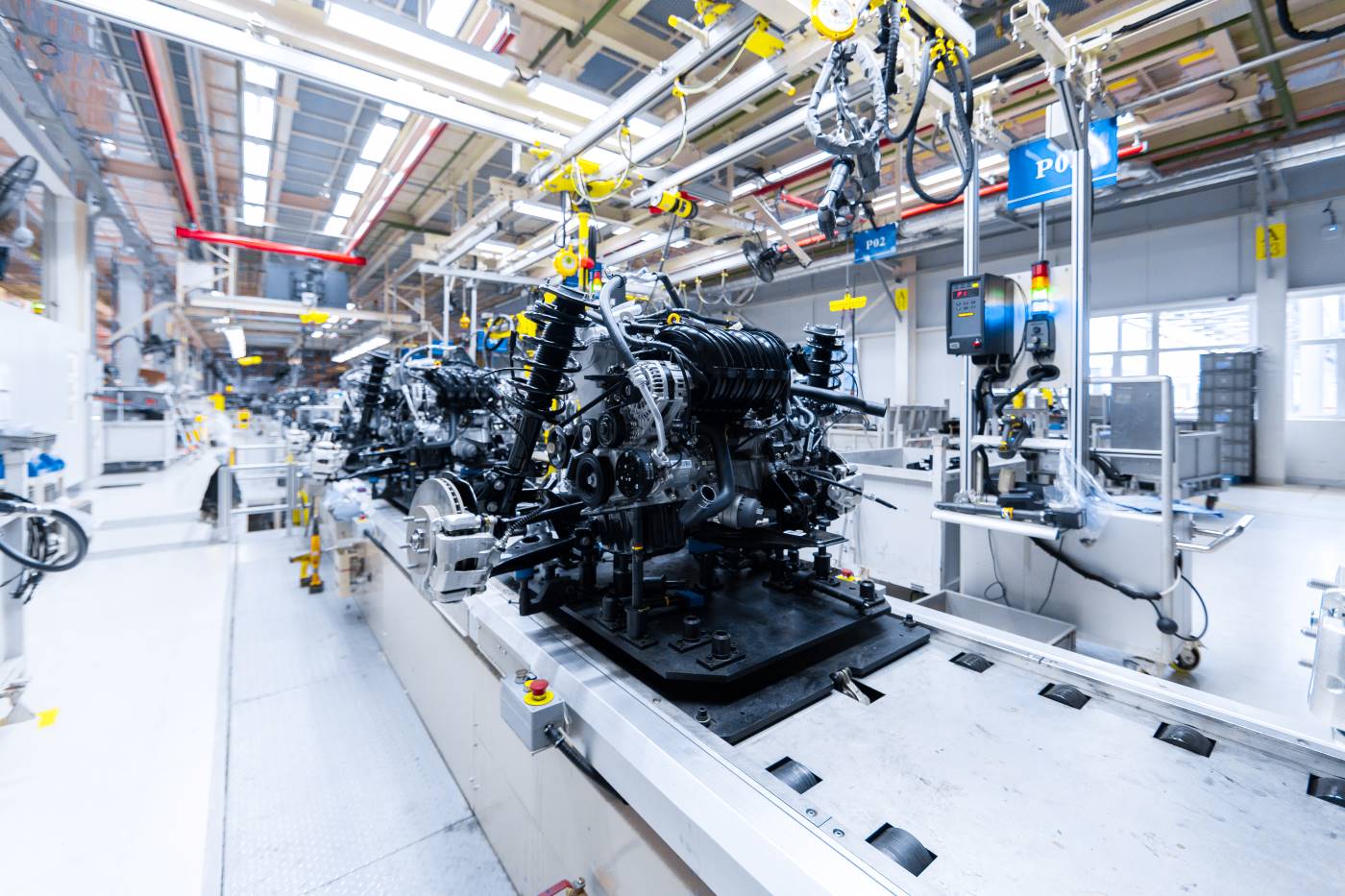

Reduction in Medication Production Time: Medication production in a pharmaceutical lab is complex and involves multiple stages. The application of Lean and TPS can help reduce medication production time by implementing standardized workflows, using Kanban to control material flow, and leveraging data analysis tools to identify bottlenecks and improvement areas. For example, a lab could use Kanban to manage raw material inventory, ensuring medications are produced quickly and efficiently.

Waste Reduction: The pharmaceutical sector deals with products that have expiration dates and require specific storage conditions. Applying Lean can help reduce waste by ensuring medications are produced in the necessary quantities and stored properly. For instance, a lab can use Lean principles to identify and eliminate unnecessary processes, reducing production time and preventing overproduction of medications.

Improved Medication Quality: Medication quality is essential for patient safety and the laboratory’s reputation. The application of TPS can help enhance medication quality by reducing wait times and increasing process efficiency. For example, a lab can use TPS to ensure medications are produced accurately and to high standards, thus improving customer satisfaction.

Enhanced Inventory Management: Inventory management is crucial in the pharmaceutical sector. Applying Lean and TPS can improve inventory management by reducing excess stock and ensuring medications are always available for patients. For instance, a lab can use Lean principles to minimize medication storage time, ensuring medications remain fresh and readily available for patients.

Cost Reduction: Applying Lean and TPS can help reduce costs for a pharmaceutical lab by eliminating waste and optimizing processes. For example, a lab can use Lean to shorten medication production time, increasing employee productivity and lowering operational costs.

This targeted approach underscores how Lean and TPS methodologies can bring operational excellence to the pharmaceutical industry, fostering quality and efficiency.