Hello, I’m Sergio Onizuka, an Advisor at Honsha.org with over 27 years of experience implementing TPS/Lean Manufacturing, Lean Office, Quality, and Maintenance. I value the legacy of preparing people so they can do something incredible and apply it to their professional and family lives.

Out of these 27 years, 14 have been spent working as a TPS/Lean Consultant in more than 70 multinational and national companies, on TPS/Lean projects in industrial, auto parts, aeronautical, services, food, administrative, hospital, and agribusiness environments. I prepare and deliver personalized training and workshops with practical mentoring for our partner clients, including Volvo Trucks, Volvo Ce, Siemens Energy, Hero Cycles, Mcassab, Ntn, Trox, Stihl, Raizen, Moove, Seb, Cargill, Fazenda Progresso, Ogma, Seb, Cbmm, Alpargatas, Kimberly-Clark, Eleb, Mars, Tecnip, among other companies in Brazil, Europe, and Asia.

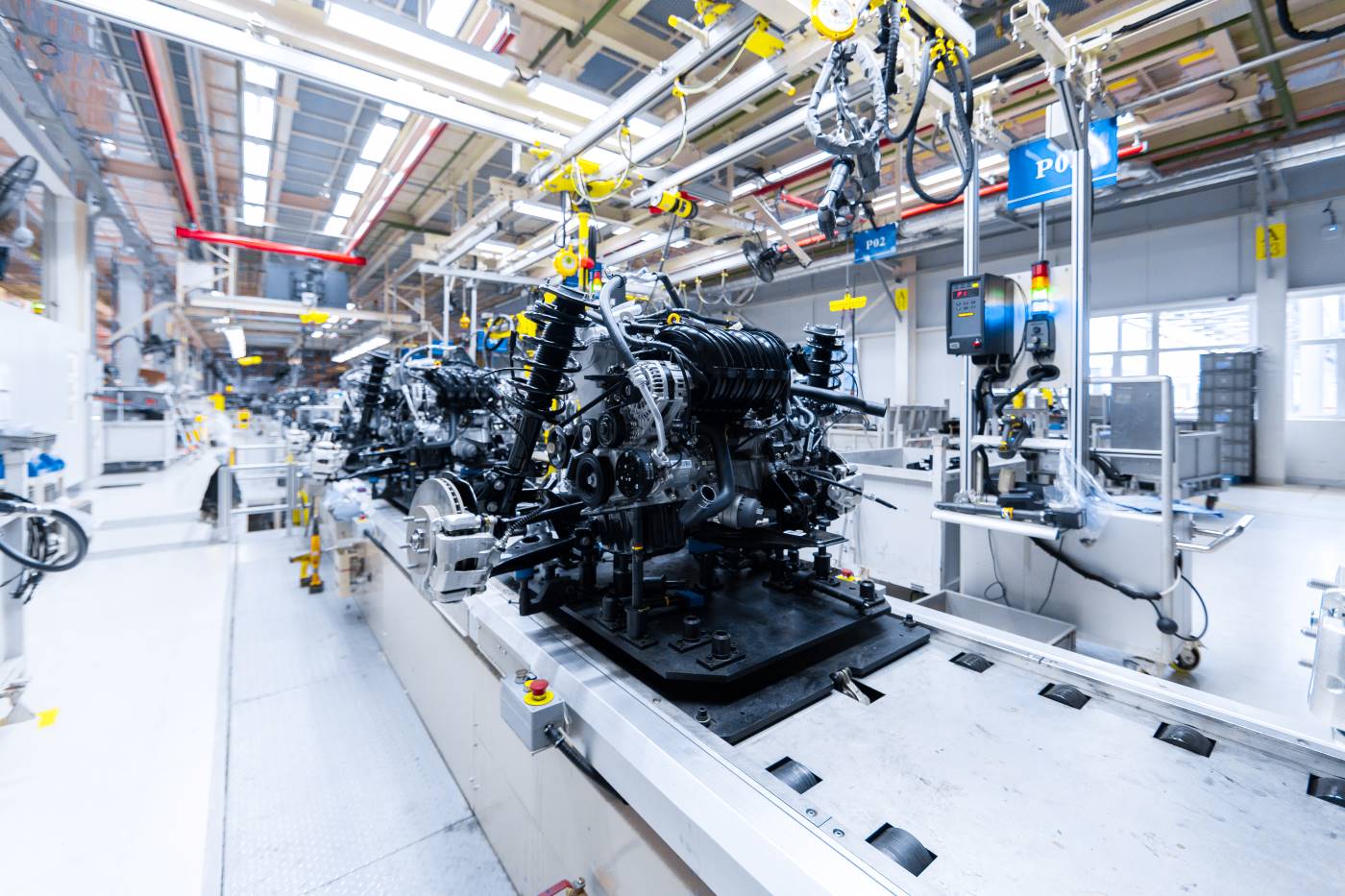

For 13 years, I worked at Toyota do Brasil in the Quality Engineering, Inspection, and Assembly department. From the Bandeirantes vehicle assembly line in 1998 to the New Hilux project in 2004, and the New Corolla from 2009 to 2011, I worked as staff on global projects, developing and implementing TPS in internal processes and at Toyota suppliers in Brazil, Argentina, and Japan. I specialized in and audited Quality validation requirements, such as Quality Assessment, QTF (Special Processes), Jikoutei Kanketsu, SQAM, ISO 9001, ISO/TS 16942, APQP, PPAP, FMEA, TBP (Toyota Business Practices), for problem resolution in production and administrative processes.

Throughout this extensive journey, I’ve had memorable experiences with our client friends in the professional, family, or voluntary work spheres. I always encounter inspiring people with many behind-the-scenes stories of building the Lean Mentality for Life. From these experiences, I learned always to put others first.

I graduated in Welding Technology from FATEC in São Paulo and received training in TPS (Toyota Production System) and Quality Management at TMC (Toyota Motor Corporation) at the Tahara and Honsha plants in Japan through the Japanese government program (AOTS) in 2004.

I also participated in Lean for Hope Digital in the 2021 edition.

In the magazine Espaço Cidad, I wrote an article about social responsibility titled “The crisis is a school of discoveries.”

I served as a guest speaker for the Lean Group at PUC/PR, discussing “The Toyota vision of Quality in Processes.”

Additionally, I spoke at the company Moove during SIPAT week on the theme “PDCA hand in hand with safety.